What is CNC Machining? | Definition, Processes, Components & More

4 min read

What is CNC Machining? | Definition, Processes, Components & More

What is CNC Machining?

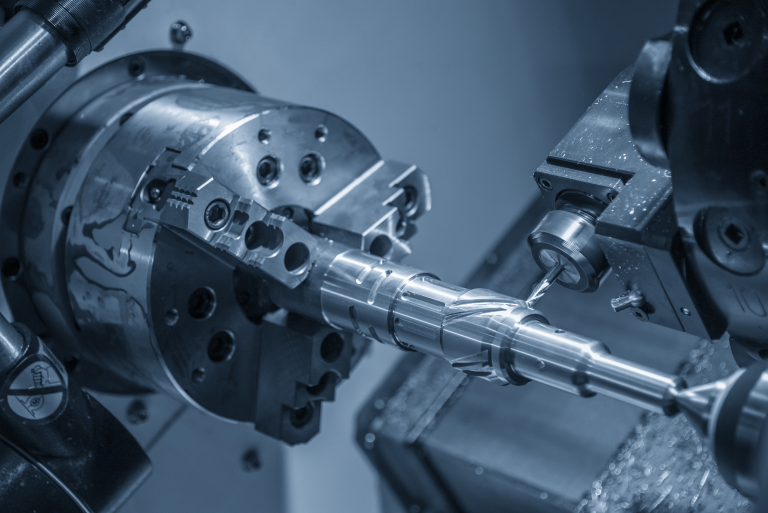

CNC means ‘PC mathematical control,’ and the CNC Turning Machine definition. Is that a subtractive creating technique utilizes processed controls and machine. Devices to dispose of layers of texture from a stock piece. known because the clear or workpiece. And produces a specially crafted part. This process is fitting for giant} shift of materials. Along with metals, plastics, wood, glass, foam, and composites, and tracks down the application in a very style of ventures. Much the same as colossal CNC machining, machining of components and models for broadcast communications, and CNC Machine part parts. That need more tight resistances than different businesses. Note there’s a qualification between the CNC machining definition and the CNC machine definition. One might be a technique and the other is a machine. A CNC Precision Machining Parts (sometimes mistakenly referre to as a C and C machine). Is a programmable machine that is fit for independently performe expressions of the tasks of CNC machining.

Are you interested in CNC Machining Administration? Attempt Xometry’s Moment Citing Engine℠ to make your undertaking return to life. Free delivery inside the USA.

CNC machining is a delivery process, and the fix is offere worldwide. You’ll have the option to immediately see CNC machining administrations in Europe. Like in Asia, North America, et al., around the globe.

Subtractive creating processes likened to CNC machining are generally given in qualification to add substance producing processes. Like 3D printing, or kind, active assembling processes. for example, fluid infusion shaping. While subtractive processes remove layers of texture from the piece of work to give custom shapes and plans. Added substance processes collect layers of material to deliver the predetermined structure. And developmental processes distort and uproot stock material into the ideal body. The programmed idea of CNC Machine permits gathering high accuracy and high exactness. direct components, and Cost-adequacy once satisfying occurring and medium-volume creation runs. In any case. While CNC machining shows bound favors over various creating methods. The level of intricacy and involution come-at-capable for. Half style and the expense viability of assembling confound parts is restricte.

While each assortment of assembling processes enjoys its benefits and impediments. This text centers around the CNC machining process. Illustrating the essentials of the process and the various components and tooling of the CNC machine. Also, this article investigates different mechanical CNC machining tasks and presents options in contrast to the CNC Machine process.

Could it said that you are between occupations immediately or a pioneer attempting to enlist? We have you fixed with our inside. Out assortments of assets for modern work searchers and businesses hoping to fill jobs. Assuming you have a vacant position. You’ll have the option to conjointly finish up our sort for a valuable chance to claim it highlighted inside the Thomas Month-to-month Update pamphlet.

Synopsis of CNC Machining strategy

Developing from the mathematical administration (NC) machining process that used punched tape cards. CNC machining might be a creating process that uses processed controls to control and control machine and slicing instruments to shape stock material e.g., Metal, plastic, wood, foam, composite, and so on into custom components and plans. While the CNC Machine strategy offers various capacities and tasks, The fundamental standards of the process stay {largely|mostly|for the most half} consistent all through every one of them. The central CNC machining process incorporates the following stages:

arranging the computer-aided design model

changing the computer-assisted design record to a CNC program

preparing the CNC machine

execution of the machining activity

Computer-aided design Model style

The CNC machining process starts with forming a second vector or 3D vital aspect computer-aided. Design configuration in-house or by a computer-aided design/CAM configuration administration organization. Programming (computer-aided design) programming licenses creators and creators to give a model. Delivery of their components and product related to the expected technical details. Much the same as aspects and calculations, for assembling the half or item.

The capacities (or failures) of the CNC machine and tooling are limited for CNC machine parts. For instance, most CNC machine tooling is tube-shape; subsequently, The part calculations feasible through theCNC Machine strategy are limited because the tooling makes twisted corner segments. Moreover, the properties of the texture being machine, tooling plan. and work holding capacities of the machine extra breaking point the look prospects. Similar to the base half thicknesses, most part size, and consideration and intricacy of inside pits and highlights.

When the computer-aide design configuration is finishe, the planner trades it for a CNC-viable document design, like STEP or IGES.

CNC Machining Resiliences Tables

Once indicating components to a machine shop, it is fundamental to consolidate any crucial resistances. The CNC machines are precise; they leave little variety between copies of steady part. Usually around + or – .005 in (.127 mm). which is generally twofold the expansiveness of a singular’s hair. To try not to squander costs. Supporters should exclusively determine resistances in the region of the. Part that may become especially right because they’ll obtain contact with various features. While there are ordinary resiliences for different machining degrees (as displayed in the tables beneath), not all resistances are equivalent. If, for instance, a region ultimately can not be more significant than the estimation. It’d have a predetermined resistance of +0.0/ – 0.5. Bring up it are much of the time somewhat more modest. but no more considerable around here.