CNC Machine Types Advantages & Disadvantages

6 min read

What are CNC Machines?

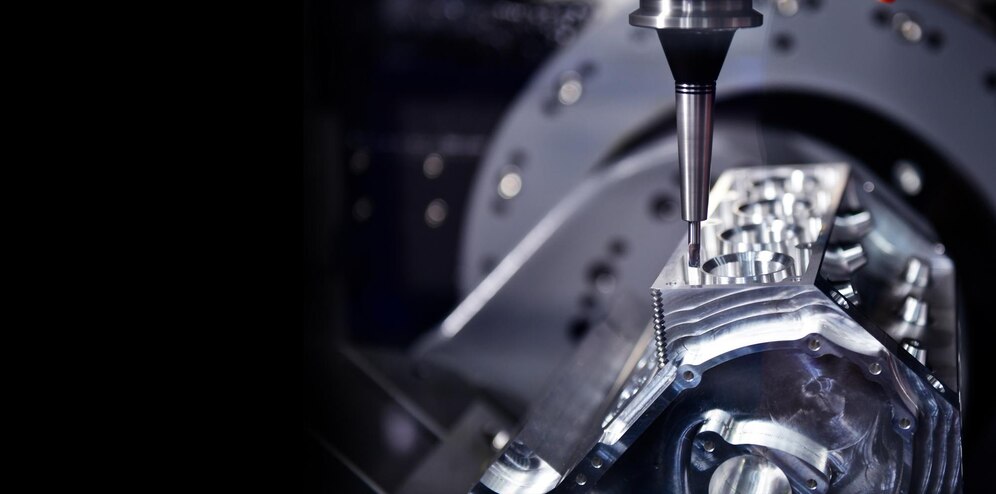

Pc Numerical administration (CNC) machines are machine-driven edge gadgets that will produce modern components without immediate human help. They utilize coded bearings shipped off an encased computer, which grants manufacturing plants the ability to create pieces precisely and rapidly. The chief typical CNC machines are CNC Milling machines, machines, and processors. Edge machines cut materials and metal precisely, utilizing a cutting shaft, which might move to various positions and profundities as coordinated by the PC directions.

Why CNC?

Favors of CNC Machine

CNC Machines enjoy the ensuing benefits –

- CNC machine will be utilize perpetually 24×7, consistently and exclusively changed for rare support.

- Each fabricated item will be exactly something similar.

- Few master/prepared people who can work CNC dislikes manual machines/milling machines, etc., which require gifted engineers.

- CNC machines can be refreshe by raising the computer code acclimate drive the machine

- Training for the appropriate utilization of CNC machines is open through the work of ‘virtual computer code’. This product is somewhat of a computer game that allows the administrator to apply double-dealing the CNC machine on the screen of a computer.

- Stylish style programming permits the fashioner to mimic the assembling of their thought. There’s no got to fabricate a worldview or a model. this safeguards time and cash.

- Exclusively the cutting apparatuses would like substitution sporadically.

CNC Machine Disadvantages

- The CNC machine administrator only wants military preparation and abilities to oversee many machines. For years, engineers expected long stretches of training to control focus machines, edge machines and different physically worked machines. This infers a few of the new abilities are being lost.

- Fewer representatives are expected to work CNC machines contraste with physically work devices. Interest in CNC machines will bring about joblessness.

- Pupils/understudies do not foster the intricate abilities required by past specialists. These exemplify numerical and designing abilities

Contrasting kinds of CNC Machining Centers-

- For a typical individual to get a handle on which kind of machining focus is open to choose from, we can express that there are essentially three sorts

- three Axis – one can strategy a profile from TOP, FRONT and BACK – X, Y and Z hub

- four Axis – one can handle a profile from TOP, FRONT, BACK and any point from FRONT to BACK – X, Y, Z and A-pivot

- Axis recommends that one will technique a profile from TOP, FRONT, BACK, any point from FRONT to BACK and LEFT to RIGHT – X, Y, Z, A, and C pivot.

Utilization of CNC Fenestration Industry-

Entryways and Windows –

The average level of Doors is 2.1m. Now and again, it ought to be 2.4m. for good measure of slippy entrances, the aspect could go up to 4.5m. Windows are ordinarily between 1.5m to 1.8m.

Machining of lock openings, keyholes, security focuses, and water discharging spaces finished every 3 Axis and four Axis machines.

Enquire Right Now For Slippy Doors

- Veneers –

- General Floor to Floor level is around 3.5m. At times, it could go up to 4.5m. The base cycle length inside the instance of veneers is 3.5m, and to downsize stacking and dumping time, a two-station machine is prudent.

- Machining openings for transom fixing, pressure accomplishment spaces, scoring at the most minimal for good measure of unitized profiles.

- tips for deciding on

- A CNC MACHINE

- Creation capacity

- most interaction length

- process Speed – Travel speed in X, Y and Z indicates the method’s speed.

- Higher speed offers higher completion. The cycle of thicker profiles could require high-voltage axles.

Transport/Oscillating activity: The machine is longer with two stations. The administrator will change the profile in Station A. this might save the season of stacking and dumping. It’s useful for Unitized veneers. Station A can technique Male Mullions. Station B can handle ladylike Mullions.

Similarity with computer code/future associations with window creation programming projects

instructing and fix.

For a better comprehension of the top of focuses, WFM incorporated essential anyway significant information in regards to the three most sizzling and broad available four pivot CNC machining habitats for Al profile process from 3 most forceful Machine enterprises showcasing to Indian façade and Fenestration market – SBZ hundred and forty from Elumatec, Salvidor Dali 70 from FOM and Orion from LGF.

Elumatec – the planet chief in machines for Al and UPVC profiles, responded to this call to foster a four-pivot device that may be quick, adaptable, and do progress machining all through the late Nineteen Nineties and mid-2000. It brought about the occasion of the SBZ 136, which developed into the contemporary SBZ hundred and forty – the leading sold profile machining focus from Elumatec around the world. Over 70 machines are stumbling into the world with window makers, drapery wall/façade makers and modern profile processors. This is, in many cases, an immense benefit for drapery wall makers.

Striking Features-

- It’s one of the fastest in its classification – 65 m/min in X pivot, 60m/min in Y and Z.

- faster axle speed for drum sander machining of Al/UPVC profiles and power twist shaft for sound applications or interaction steel.

- The shaft and Electrical pantry are outfitted with cooling frameworks to remain the controllers and axle under control temperature, empowering persistent activity.

- A more extensive Y hub permits two profile to be clasped on each station, and an X hub of 9.7m is useful for unitized drape wall makers as now and again, the slip lengths are over 4m.

- Auto length estimating decision to guarantee layered precision concerning the finish of profile.

- Enquire right now for UPVC Profiles

- FOM INDUSTRIE has fostered this CNC Machine keeping seeable high creation rate, consistency and subjective execution, and large-scale manufacturing. The machine is planned, remember the input from significant framework partnerships worldwide. It is given the right and proper specialize determinations to deal with all feasible machining on Al and PVC profiles.

Notable Features-

- Salvidor Dali seventy has two stations as a common element like this.

- Easy to use programming projects, FOM CAM and expert F2, work within the coordination of machining focus and Double Miter saw to deal with any difficulties in large-scale manufacturing.

- The construction comprises a machine bed with a pillar that slides across the most noteworthy of it. Every component is fabricate from steel and reliably steady for each work segment to guarantee that there’s no inside pressure. They’re of adequate size to guarantee steadiness and precision through machining activities.

- The tomahawks slide on high accuracy, reliable direct aid ways with recycling ball impede that have four resources outfitted with oil scrubbers and medium/high preloading.

- A “turnkey” helpful framework to determine every one of the issues underway. The organization’s mastery is at the client’s demeanour to advance. The assistance relies upon:

- A CAD-CAM framework for making a task that accommodates piece plan, programmed production of the program partner degreed recreation of the machining activities.

- An enormous chronicle is made for organizations functional in fundamental modern areas (auto, rail routes, maritime, furnishings, transport, flight-relate, material).

LGF offers an item which is progresses and portrayed by outrageous power, with the best quality/cost proportion, and conjointly offers clients heavenly adaptability and a spread of product that meets any prerequisite. Each component finds its most minor complex articulation inside. The most extensive level of inspiration. Soul of coordinated effort, perpetually supporting the justification behind LGF inside the world. in an exceedingly one amongst one in each of} the variables that to a great extent added to the progress.

Notable Features-

- Orion arrives in a bed length of four meters., seven meters.

- Chance of an exceptionally circled form that permits expanded security and is a more modest sum humming in activity.

- It will strategy profiles of lengths up to 9800 direct metric units.